Adventures In Medieval Technology

I’ve just finished the latest Great Courses offering from my favorite online professor, Stephen Ressler. The course is entitled Understanding The Marvels Of Medieval Technology and was intended as a sort of sequel to Ressler’s course Understanding Greek And Roman Technology.

The 24-lesson series starts out with an overview, naturally, and explains that the course is divided into five thematic categories. The first category is “enabling technology,” which covers such things as agricultural advances (notably, the heavy plow and the move from two-field to three-field crop rotation); working with fiber to make cloth in various ways, including a whole section that a knitter like me might call “sheep-to-shawl” (words cannot express my delight in watching Ressler try to manage a drop spindle); metallurgy and iron-making, which enchanted the part of me that loves to watch “Forged In Fire”; and two whole lessons on the various types of (and uses for) mills, mostly water mills.

The next batch of lectures covers military technologies, including knights’ armor (I enjoyed watching Ressler use clay to illustrate forge welding); what Ressler calls an “arms race” and which includes an extensive discussion of advances in archery, from the longbow to the high-powered crossbow; an intensive discussion about castle design and fortifications (those builders were really very clever); siege craft, which naturally included an in-depth discussion about the development of various forms of catapults; and the introduction and development of gunpowder weapons. I learned that the recipe for gunpowder is: 75% saltpeter, 15% carbon (usually in the form of charcoal), and 10% sulphur. You might need this information if you’re ever stranded with a Gorn. You’re welcome.

The third section of lectures covers civil and structural engineering, and spends quite a lot of time reviewing some really amazing buildings: how they were constructed, where the construction indicated small improvements on previous designs and which elements were completely new. Ressler points out that although these builders were familiar with geometry, they knew almost nothing about structural engineering and more or less built these astonishing structures without the use of scientific methods. I will cover part of one of these lectures in a little more detail below.

The fourth groups of lectures covers military technologies and mechanical systems, notably: general medieval machinery (cam shafts and pile drivers are still in use today!); the Verge-and-Foliot clock, which completely changed how people interacted with time, dividing the day into hours of equal length (Ressler builds a basic clock right in front of the viewer; it’s fantastic!); Gutenberg’s printing press, which I will address in a little more detail below; and two whole lectures on advances in ship-building, which is genuinely fascinating.

Finally, the last lecture wraps it all up but also presents a final innovation that didn’t fit neatly into any of the other categories. You’ll never guess…I know I didn’t. Glasses! Corrective eyewear. Ressler discusses what happens inside the eye to make a person long-sighted or short-sighted, and how different lenses correct the problem.

Okay, there’s my overview of the course. Now on to two parts that I found exceptionally interesting. In lecture 15 (Structural Marvels In Wood), Ressler illustrates, describes, and explains something I’d never heard of before: the Norwegian Stave Church. This structure is built in the Viking tradition and Ressler explains the basic construction thusly:

“Built entirely of pine and without a single nail or bolt, the building’s structural core is supported on four interlocking timber sills, positioned on a low stone foundation. The nave is defined by 12 cylindrical posts, which are mounted on sills interconnected with three sets of tie beams and capped with wall plates. Above the wall plates are five beautifully crafted roof trusses, which support a ridge beam, several sets of purlins, the roof planking, and an outer layer of wooden shingles. The trusses’ steep pitch and heavy timbers reflect the extremely high snow loads to which Norwegian structures are routinely subjected.”

In addition to withstanding heavy snow load, the building also needed to withstand high winds, so the builders added interior bracing of two sorts. First was some cross bracing, which was beautifully carved and decorated, adding greatly to the Nordic aesthetic. Second were wooden arches. The arches were not meant to support load like the stone arches in cathedrals, but were strictly for bracing. They were taken from the part of a tree where a branch arches away from the main trunk, and the grain of the wood followed this curve. In addition to looking really spectacular, it also increased the strength of each arch.

These buildings are just stunning and quite unlike any other churches of the era. Or really, churches of any era. I thoroughly enjoyed this part of the course.

The other topic that I wanted to describe in more detail is Gutenberg’s moveable type printing press. As Ressler points out, almost none of the technology used in the printing press was completely new. Moveable type had been in use in Asia previously, ink had been invented, paper had been invented, and of course presses had been invented. The paper being used in Europe at that time would not properly absorb the ink in common use, due to its coating (called “sizing”). Gutenberg figured out that he could soften the sizing enough to accept ink if the paper was dampened with water just slightly. But applying the water-based ink of the era to damp paper naturally resulted in ink bleeding everywhere. Gutenberg took a hint from Renaissance painters, mixing charcoal with linseed oil and a little turpentine. The resulting ink on dampened paper left a strong, clean image.

Then there was the moveable type to deal with. Given that a single page of text would require some capital letters and many lower case letters, lots of copies of each letter (and numbers and bits of punctuation) were needed. In order to generate the many copies needed, Gutenberg developed three tools.

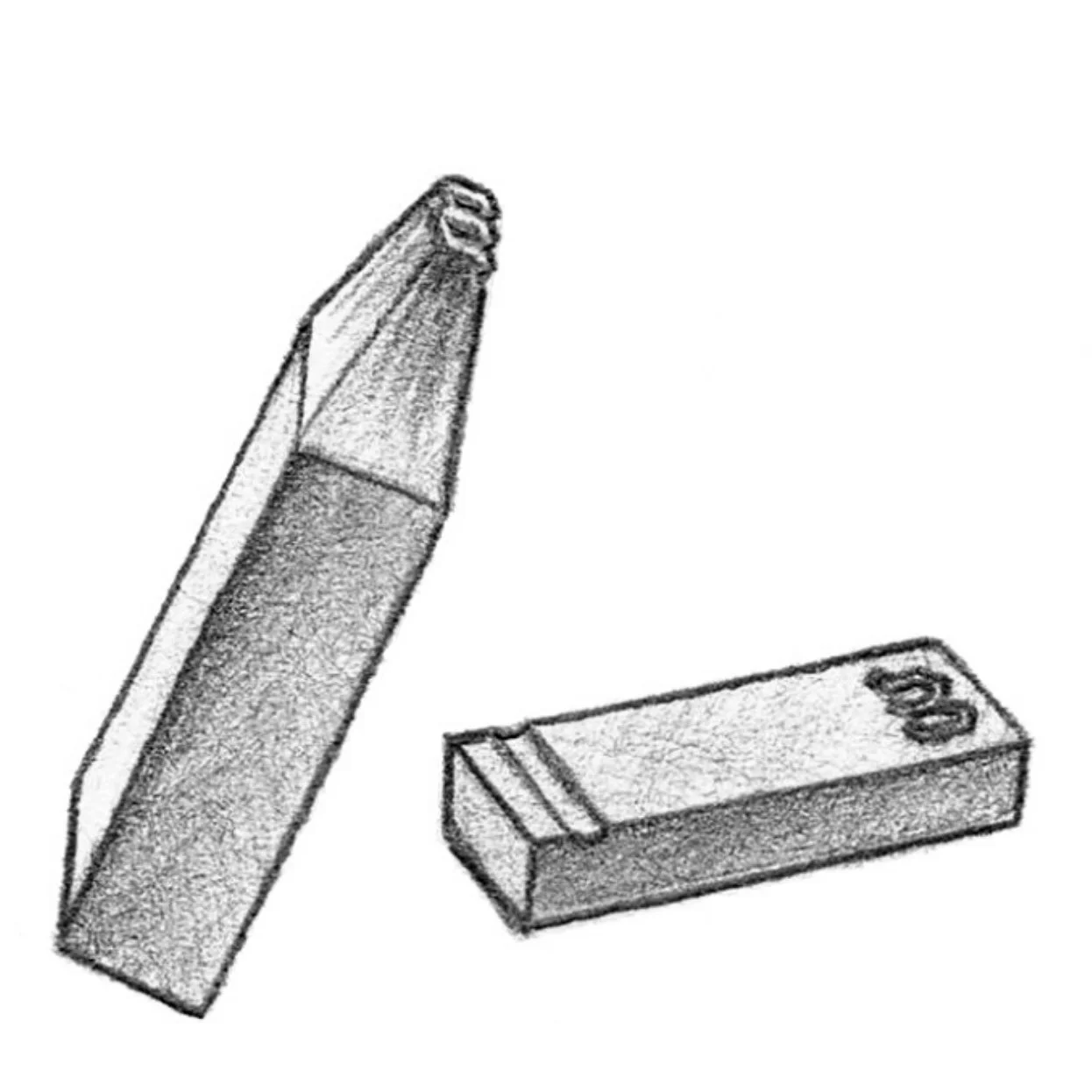

The first was a steel bar with the desired letter carved on one end in a mirror image, called a punch. The punch was then driven into a thin bar of soft copper, creating an indentation of the desired letter; the copper piece was called the matrix.

And finally, an adjustable mold was used with the copper matrix in the bottom to cast a lead alloy into the actual piece that would be used for the printing. This final piece was called the sort.

The beauty of this system is that it limited how much hand-carving had to be done, and sorts could be repeatedly cast off the matrix until the typesetters had enough. The lead sorts were relatively soft and tended to wear out, at which point more could be cast using the matrix. And when the matrix finally wore out, a new one could be stamped with the punch. It was really an ingenious system. On the case (table) that held all the sorts, the capital letters weren’t used as often, so they were on the upper part of the case, whereas the more commonly used sorts were on the lower part of the case, in easier reach of the typesetter. Thus “upper case letters” and “lower case letters” entered the lexicon. Also, when the typesetter ran out of a letter that he needed (and presumably was upset about it), he was “out of sorts.”

Gutenberg’s actual printing press was another beautifully designed system, but it’s too complicated for me to describe here. Watch the lecture! Oh, and before I forget, some of the printing press images were taken from this website, which I highly recommend looking at if you wanted more information about Gutenberg’s system.

I cannot recommend this lecture series highly enough. It’s interesting and educational, and Ressler is a highly skilled (as well as charming and entertaining) teacher. You won’t be sorry you bought the course.